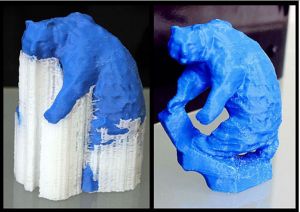

3D printed plastic is suitable for making 3D models

When conducting 3D printing, one of the important decisions that affect the physical properties and quality of 3D printing is the type of 3D printing material (3D printing plastic) suitable for 3D modeling.

This article only focuses on the most common materials for desktop 3D printers using FDM (Fused Deposition Modeling) 3D printing technology. 3D printing materials are made from a variety of resins (ABS, PLA, PVA), colors, plastic wire diameters, and lengths.

ABS (Acrylonitrile Butadiene Styrene)

ABS is used in a lot of applications in industries. Among them, can include manufacturing water pipes (drainage pipes, exhaust, …), auto parts, electronics, helmets (ABS with good impact-absorbing properties), musical instruments, toys (particularly Lego toys),… So ABS is the most suitable 3D printed plastic for making 3D models.

ABS is generally very durable and rigid, has a certain degree of flexibility and high heat resistance. In order to handle ABS 3D printing, 3D printers need a thermal printing table to limit the appearance of the 3D printed ABS models that are distorted or cracked. This type of material is suitable for many applications. Especially easily polished with sandpaper to smooth the surface and coating. 3D printed or broken parts can be easily reassembled with ABS glue. In addition, ABS can be dissolved in Acetone.

One of the major drawbacks of ABS is the evaporation of an unpleasant odor during 3D printing. Therefore, the ABS 3D printer should be placed in a well-ventilated environment. In addition, ABS can also be damaged when exposed to long periods of sunlight.

PLA (Polylactic Acid)

PLA is a primary thermoplastic synthesized from renewable sources such as corn starch and sugar cane. This makes PLA the most environmentally friendly option.

In terms of physical properties, PLA also has certain hardness, but will be slightly brittle after cooling down. The PLA melts at a lower temperature, only about 160 to 220 degrees Celsius. A thermal printing table is not required, but (at a temperature of 50-60 degrees Celsius) can improve print quality. Users can print 3D PLA in the room. Unlike ABS, PLA when heated does not emit unpleasant odors but only dissolves into Acid Lactic and smells like corn.

PLA is more difficult to glue than ABS, but can usually be solved with Cyanoacrylate (Glue 502). The drawback of this method is the need for protective clothing (masks, gloves, very tight if it touches fingers and other skin, very dry, etc.). Moreover, PLA tends to absorb water molecules in the air. PLA full of water will become brittle and harder to print (due to higher printing temperature requirements). Therefore, users need to store PLA plastic rolls in a dry environment.

PVA (Polyvinyl Alcohol)

PVA is a special plastic with water solubility.

In 3D printing, PVA is used in 3D printers with 2 nozzles, to create support structures for 3D printing models with many protruding parts (overhangs) – areas without plastic support in the lower printing layers. After 3D printing is complete, the 3D printing model can be placed in water until PVA has completely dissolved and no plastic part is supported.

3D printed plastic for making 3D model